<td id="1h9dv"></td>

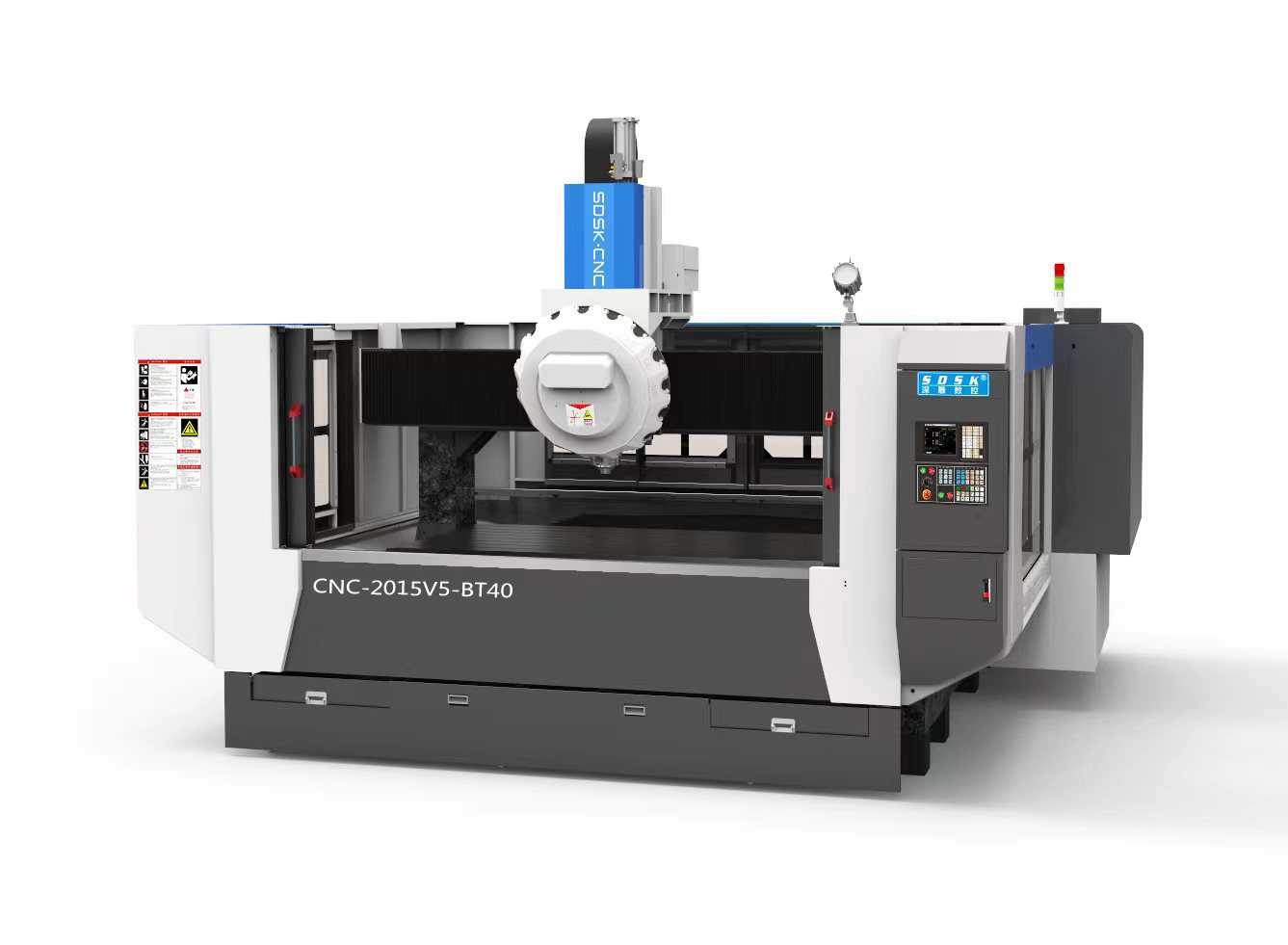

(The pictures are for reference only, subject to the actual product)

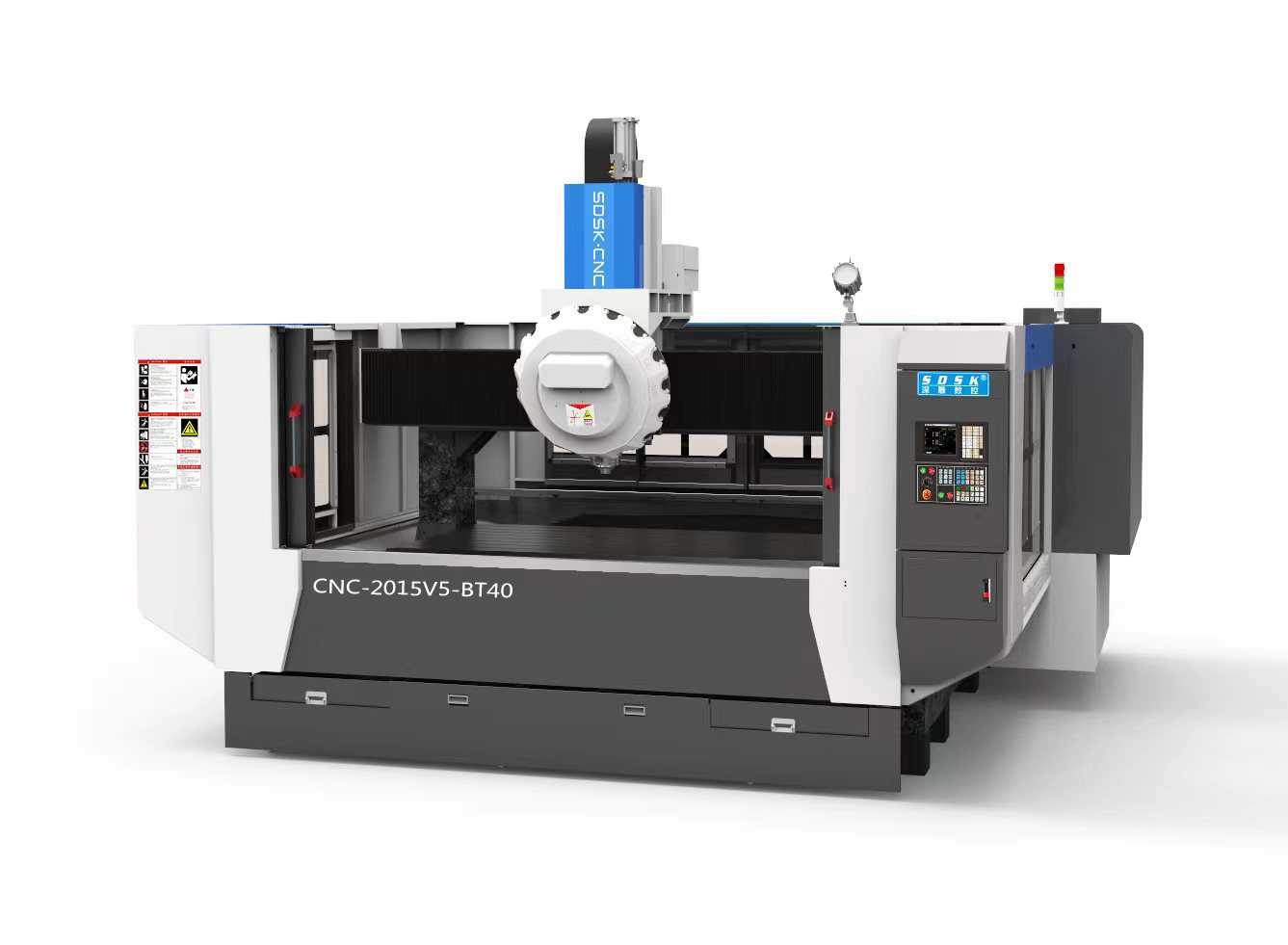

(The pictures are for reference only, subject to the actual product)

Contact:Mr.zhou

Mobile:13924586646

Telephone:0755-29423909

Email:sz_jdsk@163.com

Address:Bright new district of shenzhen hai westfield neighborhood community fourth industrial zone 6 area A house